Manufacturing

HICOOL carries out its manufacturing activities in a fully equipped facility located in Navi Mumbai, India. With over two decades of experience in the industry and with some of the most prestigious companies in its client list, HICOOL is one of the most trusted names for air moving products in India.

In order to provide products that meet the cost constraints of its customers, Hicool has invested to build a state of the art laboratory where products undergo a series of stringent testing and verification at each and every stage of the production cycle - starting from design to trial production and to mass production - in order to make sure that every Hicool product is made to customer satisfaction.

Inherent strengths HICOOL possesses

- State-of-the-art manufacturing facility

- Staff strength of over 100 qualified trained technicians

- Production Capacity of 3 Million units a year

- Complete Test Facilities.

- Fully equipped Injection Moulding Division

- In-house Tools and Dies development for: Injection Moulding, Pressure Die Cast Tools, and Motor Lamination Tools

Testing Facilities

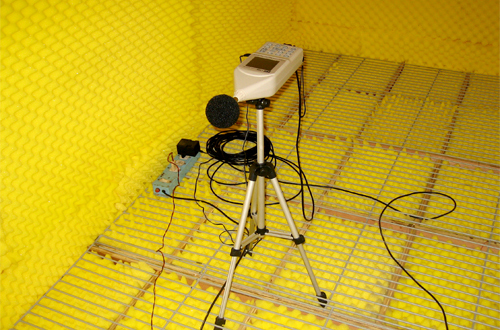

Acoustic Anechoic ChamberThe background noise is controlled below 20 dB. The software records the Noise level at different frequencies.

Airflow / Static Pressure TestingThis is performed in the early stages of product design. Airflow / Static Pressure Test is performed to understand the speed versus Air Flow / Pressure Characteristics. Moreover, to effectively resolve customers' heat dissipation problems HICOOL provides its recommendations on the type of fan to be used.

Overall Hicool Product Life Testing

Product life testing incorporates various testing environments including- High Temperature

- Low Temperature

- High / Low Temperature Circulation

- High Temperature High Humidity

- Normal Temperature, etc.

These tests are carried out to understand the changes of service life of HICOOL products in different use environments. Hence any fan failure can be detected real time and the product life can be estimated. Products are tested in design phase, through pre-production and into mass production.

Concern for Environment

HICOOL deeply recognizes its corporate duty to protect our earth and the ecosystem and to reduce the use of material that impact the environment. In light of this HICOOL has been actively promoting RoHS (Restriction of Hazardous Substances) compliant products.